Thaum cov neeg siv khoom siv CNC ntsug machining chaw kom paub txog kev ua tiav, lawv feem ntau ntsib qhov tsis ruaj tsis khov kev tsheb ciav hlau raug lossis lwm yam xwm txheej.Lub sijhawm no, lawv yuav tsum tau kho cov tsheb ciav hlau hauv lub sijhawm.Thaum tag nrho cov txheej txheem calibration, xyuam xim rau peb qhov teeb meem kom tsis txhob muaj qhov tshwm sim ntawm txoj kev tsheb ciav hlau.s kev puas tsuaj.

1) Xav txog lub zog txhua yam ntawm cov txheej txheem kho nws tus kheej thiab qhov chaw ua haujlwm tiag tiag ntawm txoj kev tsheb ciav hlau.Hais txog qhov sib txawv ntawm cov qauv siv, kev ua tau zoo, thiab kev ua haujlwm ib puag ncig, thaum kho, kev kho vuam thiab kev kho cov nplaum yuav tsum tau ua raws li qhov xwm txheej tiag tiag, thiab cov txheej txheem kho kom zoo thiab cov txheej txheem yuav tsum tau siv.

2) Xav txog seb cov txheej txheem xaiv puas muaj feem cuam tshuam rau qhov raug thiab cov khoom siv ntawm cov kev taw qhia rail.Yog tias nws raug cuam tshuam los ntawm qhov kub thiab txias, txawm tias nws yuav ua rau cov kev taw qhia rail deform, seb nws puas yuav hloov lub zog ntawm lub zog thiab qhov tawv tawv ntawm cov kev taw qhia rail.

3) Xav txog cov txheej txheem calibration xaiv thiab qhov tsim nyog ntawm cov ntaub ntawv qhia kev tsheb ciav hlau.

Lub perpendicularity thiab parallelism ntawm cov kev taw qhia rails thiab qhov ncaj ntawm cov kev taw qhia rail nyob rau hauv lub dav hlau yuav cuam tshuam cov geometric raug ntawm CNC ntsug machining chaw.Cov lus qhia kev tsheb ciav hlau qhov tseeb kuj yog qhov nyuaj dua.Cov khoom siv lub cev, cov qauv, thiab cov khoom siv tes ua txhua yam yuav txiav txim siab txog kev qhia kev tsheb ciav hlau raug..

Kev cuam tshuam ntawm kab rov tav qhov tseeb ntawm CNC ntsug machining chaw tuaj yeem raug sau tseg rau hauv peb lub ntsiab lus hauv qab no:

1. Yog hais tias qib tsis ncav cuag qhov kev teev tseg, CNC ntsug machining chaw yuav ua rau lub deformation ntawm cov kev taw qhia rail thaum lub sij hawm ntev ua hauj lwm, thiab lub verticality ntawm X thiab Y axes kuj yuav cuam tshuam.

2. Tom qab cov kev taw qhia rail yog deformed, lub worktable kuj yuav deformed.Hauv qhov xwm txheej no, qhov ntsug ntawm qhov ntxaiv thiab lub rooj ua haujlwm yuav ua rau mob hnyav dua, thiab qhov tshwm sim yuav cuam tshuam rau lub dav hlau machining qhov tseeb ntawm CNC ntsug machining chaw.

3. Tag nrho cov kev pab cuam lub neej ntawm cov lus qhia ntsia hlau thiab CNC ntsug machining chaw yuav raug txo.

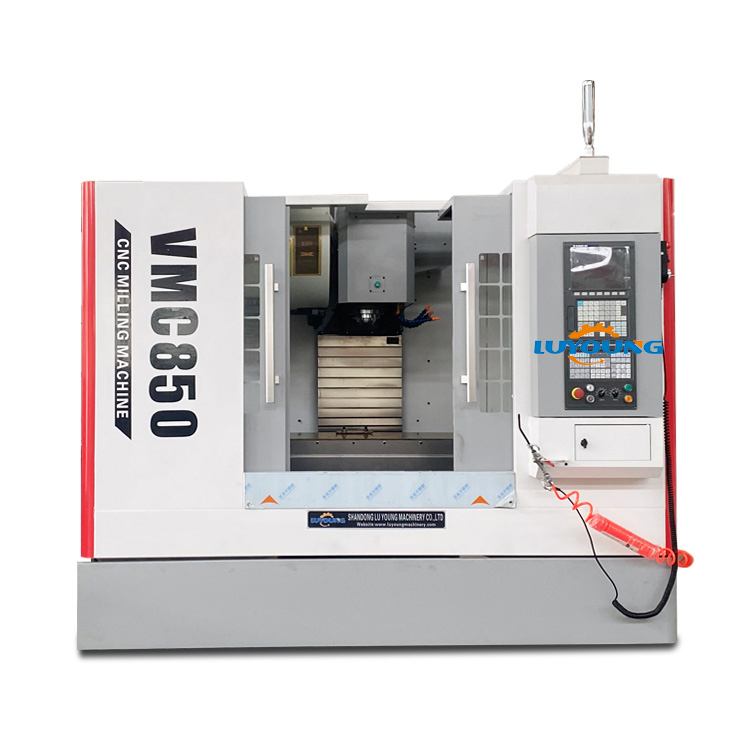

Txais tos los sab laj peb CNC ntsug machining chaw: vmc420, vmc7126, vmc550, vmc650, vmc850, vmc1060, thiab lwm yam. Peb muaj 20 xyoo ntawm kev tsim khoom thiab muab cov khoom zoo thiab cov kev pabcuam zoo.

Post lub sij hawm: Dec-10-2021