Specification

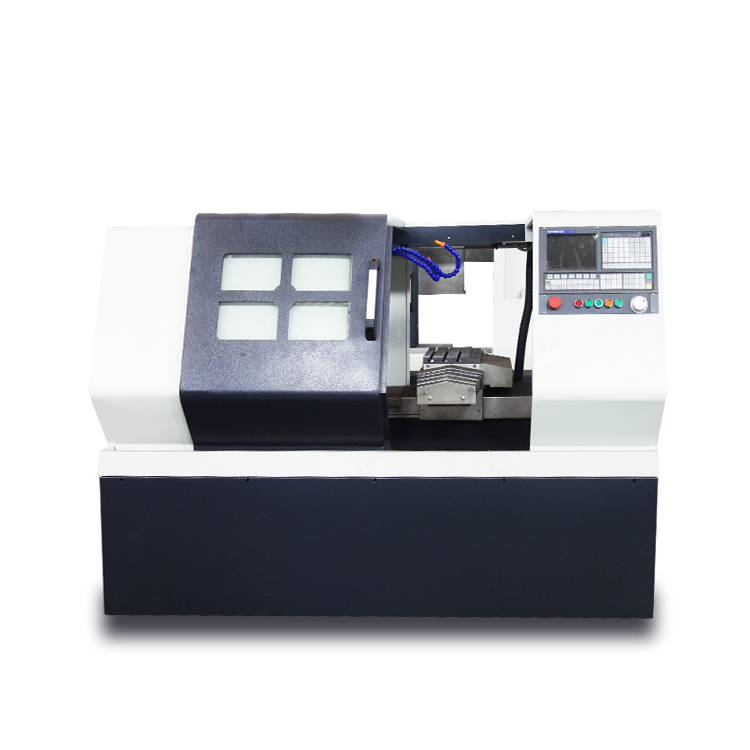

| Linear Guideway CNC Tshuab dhos tshuab H36 | |

| max.viav vias saum txaj | Φ360 hli |

| max.viav vias hla swb | Φ110 hli |

| Chuck/collet | Pneumatic lub tog raj kheej |

| X axis taug kev | 340 hli |

| Z axis taug kev | 500 hli |

| Qhia txoj kev | Kev kub ceev linear qhia txoj kev |

| Spindle ceev | 3000 rpm |

| Spindle qhov ntswg | A2-5 |

| Spindle bore | Φ48 hli |

| Bar los ntawm spindle | Φ38 hli |

| Ceev ceev pub mis | X: 20 Z: 20 m / min |

| Main lub cev muaj zog | 3.7KW servo lub cev muaj zog |

| Tool loj | 20 * 20 hli |

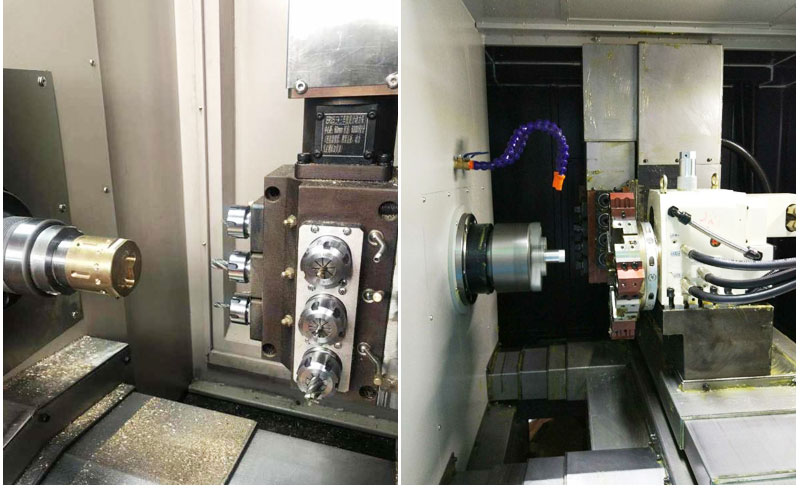

| Tool kom muaj nuj nqis | gang hom cuab yeej tuav |

| X/Z min set unit | 0.001 hli |

| X/Z positionaI qhov tseeb | 0.01mm ib |

| X/Z Repositioning raug | 0.005 hli |

| Demension | 2600 × 1600 × 1800 hli |

| Qhov hnyav | 1.2 T ib |

yam ntxwv

1.H36 Kab rov tav zoo cnc tshuab dhos tshuabnrog cov cuab yeej ua neej

Electromechanical integration tsim, aesthetic tsos, tsim nyog qauv, kev ua tau zoo tus nqi siab thiab tus nqi siab ntawm txoj kab tsheb ciav hlau.

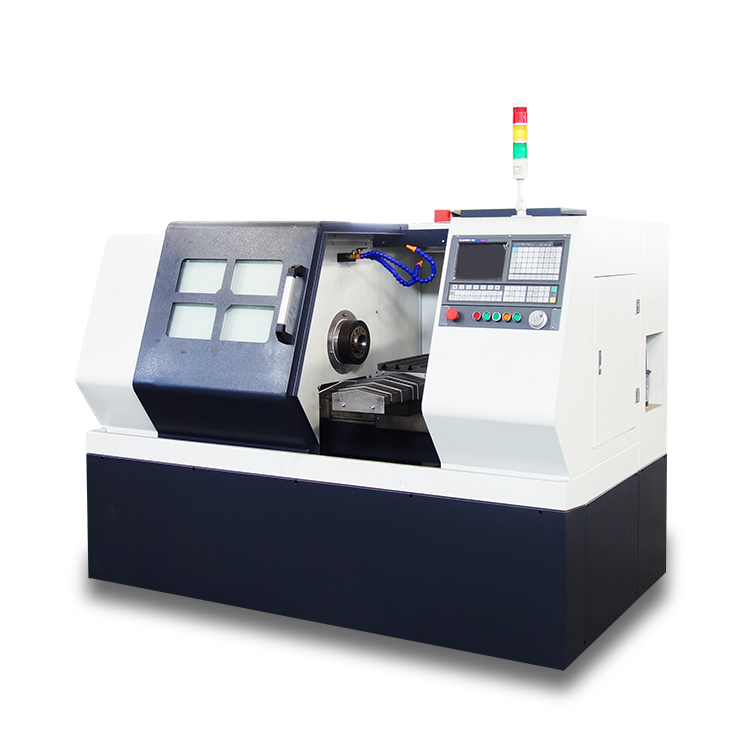

2..linear qhia txoj kevInclined txaj lub cev casting, tiv thaiv deformation, txhim kho rigidity thiab precision.

3. CovH36 me cnc tshuab dhos tshuablub ntsiab ncej txais lub precision spindle chav tsev, lub radial pulsation yog me me, lub lag luam yog du, lub suab yog me me, ceev yog siab, kev pab cuam lub neej ntev, lub siab tshaj plaws ceev ntawm lub ntsiab ncej ntawm luoyang yuav ncav cuag txhua feeb 4000 RPM.Qhov siab tshaj plaws rotating ceev ntawm lub ntsiab ncej ntawm Taiwan posen tuaj yeem ncav cuag 6000 revolutions ib feeb.Adopt servo spindle tsav, ceev tso zis torque loj.

4.H36 linear qhia txoj kev cnc tshuab dhos tshuabKab rail thiab ntsia hlau pas nrig txais yuav Taiwan cov khoom siv nyiaj, siab raug, kev ua haujlwm zoo, ruaj khov, ceev tuaj yeem ncav cuag 20 meters ib feeb.

5. Txais yuav guangzhou CNC 980TB thiab 980TD system nrog cov haujlwm muaj zog, cov lus teb ceev thiab ua haujlwm yooj yim.

6. CovH36 cnc tshuab dhosspindle lub cev muaj zog tuaj yeem siv rau hauv lub ntsiab ncej ntawm guangzhou cov lej tswj, uas tuaj yeem paub qhov quasi-nres, tuav lub nres, faib qhov nrawm, ruaj khov, thiab lav qhov qis qis thiab siab torque.Lub taub hau fais fab paub txog lub milling coincidence.

7. Clamping hom, siv hydraulic chaw nres tsheb, hydraulic rotary roj lub tog raj kheej, hydraulic chuck thiab raj clip.Lub clamping quab yuam yog loj, ruaj khov thiab yooj yim los hloov.

Lub sij hawm xa tuaj: Mar-11-2022